The oil and gas industry operates within a highly complex and demanding environment where equipment reliability, safety, and regulatory compliance are critical for sustainable operations. As companies face increasing pressures to maximize efficiency and reduce downtime, CMMS software for oil and gas has emerged as an essential tool to manage maintenance activities effectively. ValueApex (Shanghai) Information Technology Co., Ltd., through its proprietary solution EAMic®, offers a CMMS oil and gas platform designed specifically to address the unique challenges of this sector. The integration of such advanced software solutions transforms maintenance management from reactive to proactive, ensuring optimal asset performance and operational continuity.

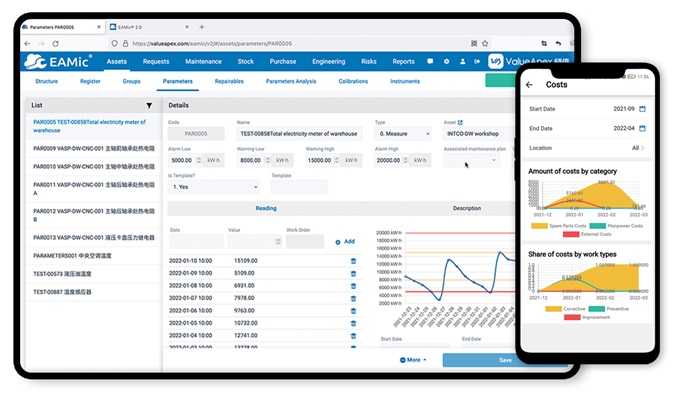

In the oil and gas industry, managing a vast array of equipment including pumps, compressors, pipelines, and offshore platforms demands a robust system capable of handling complex maintenance schedules and regulatory requirements. CMMS software for oil and gas helps organizations centralize asset data, automate maintenance workflows, and improve visibility into equipment health. EAMic® provides industrial enterprises with a comprehensive platform that enables preventive and predictive maintenance, reducing unexpected failures and extending asset lifespan. This oil and gas equipment maintenance software ensures that maintenance teams can plan and execute tasks efficiently, maintaining high operational standards in environments where downtime can be extraordinarily costly.

The deployment of a CMMS oil and gas system offers measurable benefits that extend beyond routine maintenance. By leveraging data-driven insights, EAMic® empowers maintenance managers to prioritize tasks based on real-time asset conditions and historical performance. This level of intelligence reduces unnecessary maintenance activities, optimizing resource allocation and lowering operational costs. Furthermore, stringent safety regulations in the oil and gas sector require meticulous tracking of inspections and compliance documentation. CMMS software for oil and gas simplifies this process by automating compliance tracking, thereby minimizing risks related to regulatory breaches and ensuring safer working environments.

Aspect | Traditional Maintenance | CMMS Software for Oil and Gas (EAMic®) |

Maintenance Scheduling | Often reactive, leading to unplanned downtime | Preventive and predictive scheduling to minimize disruptions |

Data Management | Manual and fragmented records | Centralized, real-time data accessible across teams |

Compliance Tracking | Paper-based and error-prone | Automated alerts and documentation for regulatory adherence |

Spare Parts Inventory | Inconsistent tracking, risk of shortages | Real-time inventory monitoring and automated reorder triggers |

Work Order Execution | Delays due to poor communication and manual processes | Streamlined digital workflows with mobile access |

This comparison highlights how CMMS software like EAMic® revolutionizes maintenance management by providing a more systematic and transparent approach, ultimately improving asset availability and operational reliability.

Safety is a paramount concern in oil and gas operations, where equipment failure can lead to catastrophic consequences. CMMS oil and gas solutions such as EAMic® contribute to a safer workplace by enforcing rigorous maintenance schedules and ensuring that all safety inspections and certifications are up-to-date. The ability of this oil and gas asset software to document every maintenance activity creates an auditable trail that supports compliance and accountability. Additionally, by reducing unexpected breakdowns and facilitating faster response times, CMMS software enhances operational efficiency and helps maintain continuous production, which is critical in this sector.

Long-term asset management is a significant challenge in the oil and gas industry due to the harsh operating conditions and the extensive lifecycle of equipment. EAMic® offers advanced equipment lifecycle tracking, allowing companies to analyze asset performance over time, optimize maintenance strategies, and make informed decisions regarding repairs or replacements. The scalability of CMMS software for oil and gas enables enterprises to standardize maintenance practices across multiple sites, ensuring consistent quality and efficiency. This strategic approach not only reduces costs but also supports sustainable growth and competitiveness in the industry.

In conclusion, CMMS software for oil and gas, exemplified by ValueApex’s EAMic®, is a critical enabler for efficient, safe, and compliant operations. By transforming maintenance management through automation, data integration, and proactive planning, such solutions address the unique challenges of the oil and gas sector and help companies maintain a competitive edge while safeguarding their assets and workforce.