In the rapidly evolving landscape of modern industry, digital transformation is no longer optional—it's imperative. A spare parts management system such as ValueApex's EAMic® plays a central role in this shift. By digitizing and centralizing the tracking of components, usage, and procurements within asset maintenance workflows, this spare parts management system serves as a robust catalyst for operational modernization.

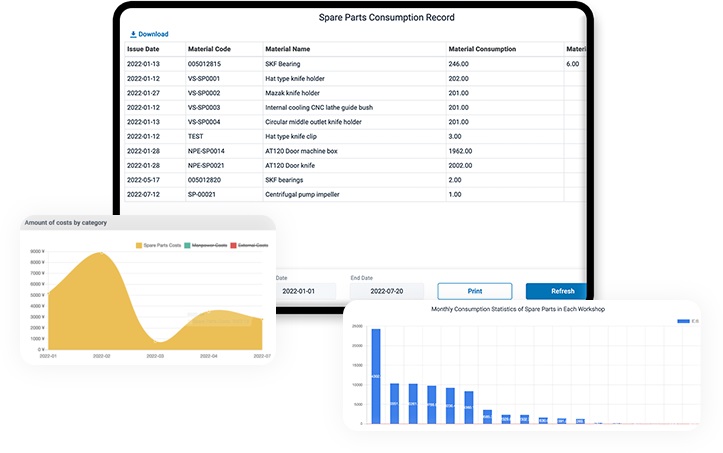

Spare parts management system establishes comprehensive spare parts information files, enabling transparent sharing of data across the organization. By capturing and consolidating information—from part codes and technical specifications to warehousing and consumption details—the system ensures that planners and maintenance teams have timely, consistent visibility into inventory dynamics. This digital vision transforms reactive firefighting into proactive planning, allowing enterprises to adjust outsourcing and stocking decisions with precision.

Spare parts management system enforces discipline in spare parts usage by controlling warehouse outflows and requisitions. It prevents over-collection and disorderly consumption and tracks part destinations, enabling financial transparency and cost optimization. Through intelligent inventory modeling, spare parts management system contributes to reduced capital lockup in surplus stock, improved capital utilization, and savings of approximately 9 % to 15 % in spare parts costs.

Aspect | Traditional Practices | EAMic®-Powered System |

Information Visibility | Fragmented, siloed data prone to inconsistencies | Unified, transparent digital parts information files |

Stock Control | Manual tracking, frequent overstock and shortages | Automated alerts for minimum stock levels and zero oversupply |

Procurement Reaction | Reactive, slow, based on guesswork or emergencies | Data-driven adjustments and planned requisitions |

Cost Visibility | Limited insight into consumption and financial impact | Clear tracking of part destinations, delivery, and costs |

Digital Integration | Isolated systems with limited connectivity | Seamless interoperability with ERP/WMS via API syncing |

This comparison clearly demonstrates how EAMic® elevates maintenance operations by embedding intelligence, automation, and transparency where traditional methods fall short.

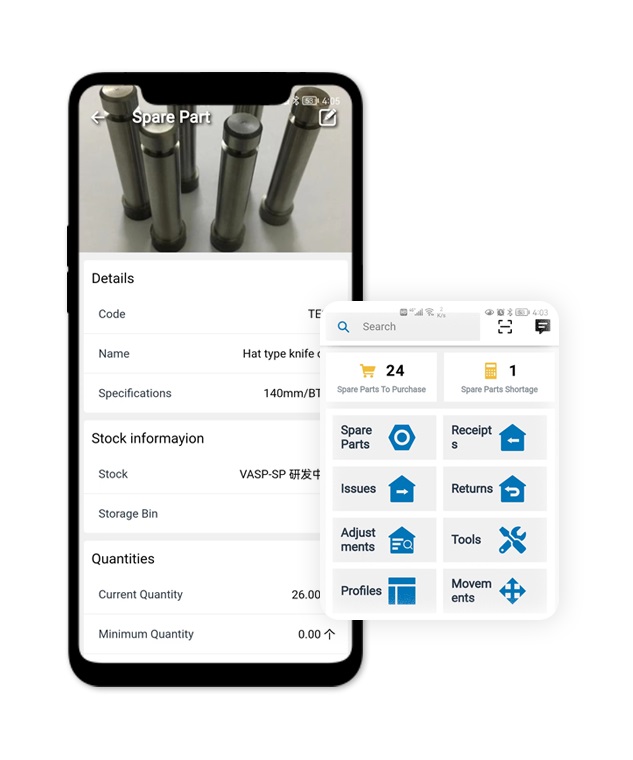

A digital spare parts management system is instrumental in sustaining production reliability. EAMic® ensures essential parts for critical equipment are available when needed, significantly reducing the risk of unplanned downtime. Through real-time inventory insights and proactive alerts, spare parts management system helps maintain continuity in operations and supports maintenance teams in preserving uptime and equipment health.

Embedding spare parts management system within a broader digital maintenance ecosystem amplifies its impact. EAMic® integrates seamlessly with other CMMS modules—such as preventive maintenance, work order management, and inspection tracking—while its mobile app ensures access anytime, anywhere. Additionally, integration with ERP or WMS systems enables a cohesive ecosystem where issues like material lists, stock movements, and procurement data flow effortlessly across platforms.

Through intelligent resource planning, cost control, and seamless integration, a modern spare parts management system like EAMic® becomes a foundational enabler of digital transformation. By transitioning organizations from paper-based silos to proactive, data-driven operations, it offers a clear path toward greater efficiency, reliability, and strategic agility.