Preventive Maintenance (PM) is the cornerstone of ensuring equipment reliability, and professional software is an efficient tool for executing PM strategies. The market offers various types of equipment preventive maintenance software, which can be mainly categorized as follows based on their functional depth and technical approach.

This is the most basic and widely used preventive maintenance software, core to executing maintenance based on schedules and rules.

Core Functions: Focuses on "managing" maintenance work. Automatically generates preventive maintenance work orders by setting time cycles or equipment run counters and manages their execution workflow.

Preventive Mode: Based on fixed time or usage, belonging to scheduled maintenance.

Applicable Scenarios: Equipment whose failure modes have a clear, stable relationship with time or usage. Suitable for the conventional maintenance needs of most enterprises.

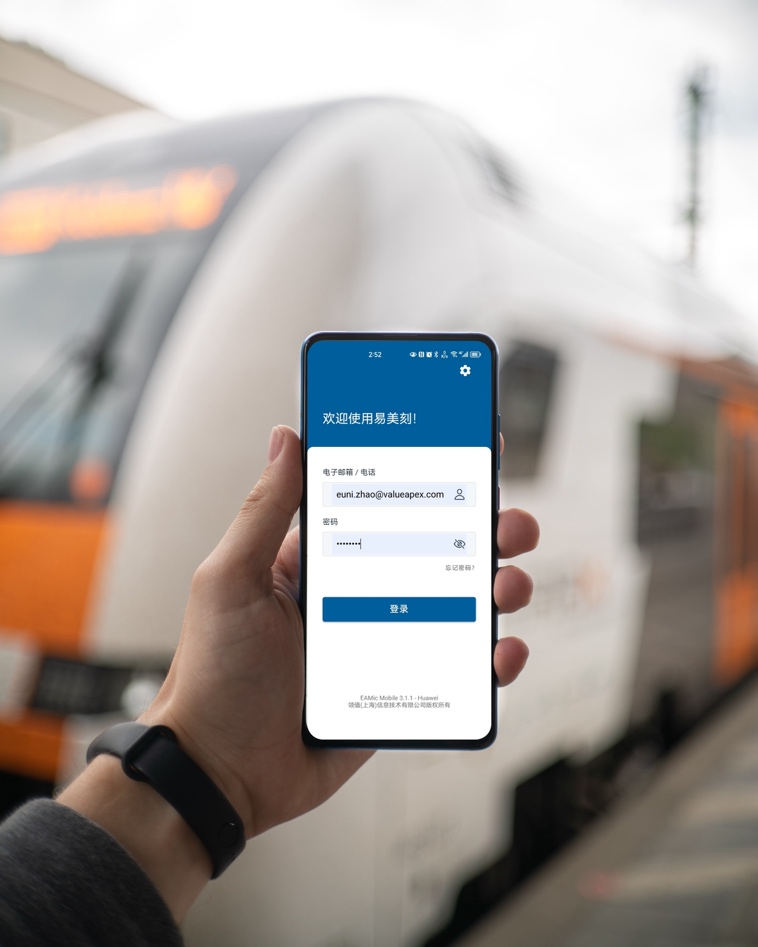

Typical Vendors: UpKeep, Limble CMMS, Fiix, eMaint, ValueApex EAMic.

This is an upgraded version of CMMS, making the triggering of preventive maintenance more precise through integrated sensor data.

Core Functions: Builds upon traditional CMMS functions by adding real-time equipment condition monitoring. The system can trigger inspections or maintenance tasks based on the actual condition of the equipment, not just fixed cycles.

Preventive Mode: Condition-Based Maintenance. Issues early warnings when data indicators approach alarm thresholds.

Applicable Scenarios: Suitable for critical equipment, aiming to reduce unnecessary periodic maintenance and achieve more targeted "on-demand" maintenance.

Typical Vendors: Most modern CMMS vendors support IoT integration, as well as large systems like IBM Maximo, Infor EAM.

This is a more advanced form of preventive maintenance, utilizing AI and big data for failure prediction.

Core Functions: Uses machine learning algorithms to deeply analyze equipment sensor data, predict future failure probability and remaining useful life, and provide early warnings before failures occur.

Preventive Mode: Predictive Maintenance. It answers, "When will the equipment fail?".

Applicable Scenarios: Suitable for high-value, complex critical equipment where downtime loss is significant, and failure has a noticeable degradation process. Higher technical and financial barriers, but ROI can be very significant.

Typical Vendors: Augury, Senseye, Uptake, ValueApex EAMic, and predictive analytics solutions from industrial giants like GE Digital, Siemens, PTC.

Many comprehensive EAM systems have powerful built-in preventive maintenance modules.

Core Functions: PM functions are similar to CMMS, but their biggest advantage is data integration. Equipment maintenance data seamlessly connects with finance, procurement, inventory, and project modules, facilitating the planning and optimization of preventive maintenance strategies from a total lifecycle cost perspective.

Applicable Scenarios: Suitable for large asset-intensive enterprises with high standards for financial and asset control.

Typical Vendors: IBM Maximo, SAP PM, Oracle EAM, Infor EAM, ValueApex EAMic.

Enterprise selection depends on:

1. Equipment Complexity & Value: Low-value, simple equipment can use CMMS; high-value, complex equipment should consider IoT CMMS or PdM.

2. Maintenance Maturity: Enterprises starting from traditional maintenance can begin digitalization with CMMS; those with a good PM foundation can explore predictive maintenance.

3. Budget & ROI: CMMS has lower costs; PdM requires higher investment but can yield extremely high returns.

4. Integration Needs: Whether deep integration with existing ERP, MES, etc., systems is required.

There is no single "best" software, only the "most suitable" one. Enterprises should clearly define their preventive maintenance goals and pain points, start by solving the most pressing problems, and choose a solution with a matching technical approach and high cost-effectiveness.