The Smart Operations Dispatch & Inspection System is the core operational platform for modern equipment management. It fully digitizes and intellectualizes traditional repair, inspection, and maintenance work through mobile internet, cloud computing, and IoT technologies, and empowers managers with powerful data analysis capabilities. This article details its five core functional modules.

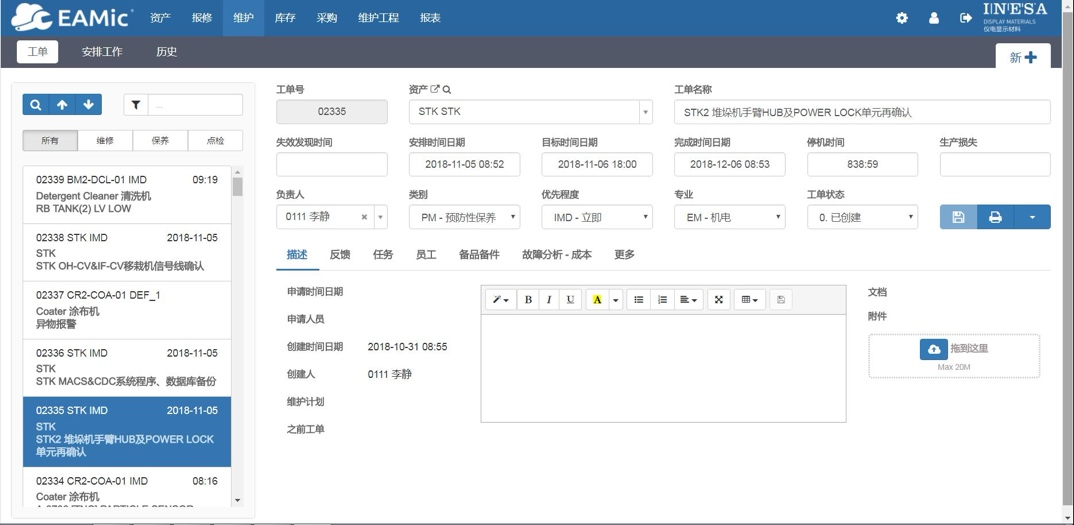

1. End-to-End Work Order Management:

Multi-Channel Request: Supports PC, mobile APP, QR code scanning, etc., with photo/voice descriptions for precise and efficient communication.

Intelligent Dispatch: The system automatically recommends or assigns the most suitable personnel based on fault type, location, urgency, technician skills, location, and current workload, greatly improving dispatch efficiency.

Mobile Execution: Technicians receive work orders via APP, view equipment history/manuals/drawings, request spare parts online, and update work order status in real-time.

Knowledge Retention: Upon work order closure, recording failure cause, actions taken, and spare parts used is enforced, forming a solution knowledge base for rapid handling of similar future faults.

1. Standardized Inspection Plans:

Plan Creation: Set inspection routes, cycles, check items, standard values, and safety items for different equipment and areas.

Mobile Execution: Inspectors use the APP to execute tasks according to predefined routes, scan equipment QR codes/NFC tags to confirm presence, and directly input measured data.

Automatic Anomaly Reporting: When input data exceeds standard ranges, the system automatically generates anomaly work orders, triggering the repair process for early problem detection and resolution.

Prevent Leaks & Fraud: GPS positioning, scan-based check-ins, and sequential execution effectively prevent missed/false inspections and data fabrication.

1. Preventive Maintenance Automation:

Plan Triggering: The system automatically generates maintenance work orders based on time cycles or equipment runtime meters.

Task Templating: Maintenance content, steps, required tools, and spare parts can be preset as templates, ensuring standardization and consistency.

Execution & Recording: Technicians perform maintenance according to the template, record results and potential issues found; all records are traceable, providing basis for equipment health assessment.

This is the "brain" of smart operations, transforming the massive data from the first three modules into business insights.

1. Visual Dashboards:

Real-Time Monitoring: Centrally displays key performance indicators like current work order status, down equipment list, overdue work, inventory levels, etc., at a glance.

2. In-Depth Analysis Reports:

Equipment Reliability Analysis: Automatically calculates and displays MTBF, MTTR, OEE, identifying weak equipment.

Maintenance Performance Analysis: Analyzes Planned Maintenance Percentage, work order completion rate, personnel efficiency, maintenance cost trends, measuring team performance.

Inventory Optimization Analysis: Performs spare parts ABC classification, obsolete inventory analysis, inventory turnover rate calculation, guiding precise procurement.

Root Cause Analysis: Uses tools like Pareto charts to identify the vital few failure modes causing most downtime/costs, guiding technical improvements.

These four functional modules are not isolated but form a tightly collaborative closed loop: problems found during inspection and maintenance automatically trigger repair work orders; maintenance records, in turn, provide data for statistical analysis, which then optimizes inspection and maintenance strategies and plans. Ultimately, the smart operations system achieves standardized workflows, transparent execution processes, and data-driven decision support, significantly helping enterprises improve equipment reliability, reduce maintenance costs, and optimize resource allocation.