In today's competitive industrial environment, the need for efficient maintenance practices cannot be overstated. A well-organized spare parts management system is essential for ensuring that manufacturing processes run smoothly, minimizing downtime, and optimizing operational efficiency. With the increasing complexity of industrial assets and machinery, companies must move away from outdated manual processes and embrace digital solutions like ValueApex's EAMic® spare parts management system to stay ahead.

A spare parts management system goes beyond simple inventory tracking; it is integral to the maintenance strategy of industrial enterprises. With the ever-growing need for continuous production, ensuring that essential spare parts are always available is crucial. EAMic® from ValueApex delivers a highly effective solution for tracking spare parts, monitoring inventory levels, and preventing shortages or overstocking.

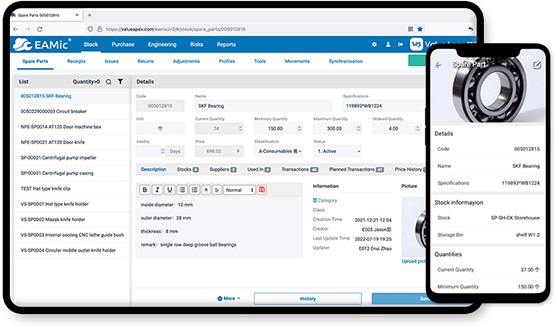

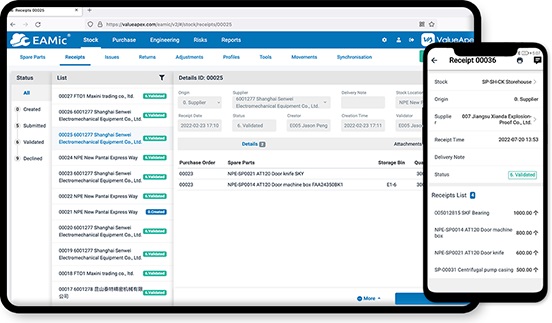

EAMic® allows companies to digitize and centralize spare parts management, creating a more accurate and organized process. The spare parts management system enables real-time tracking of parts, from warehouse storage to usage in the field, allowing maintenance teams to quickly assess inventory levels and make informed decisions. With automated alerts for low stock levels, the system ensures that parts are reordered just in time, preventing costly delays caused by missing components.

ValueApex's EAMic® spare parts management system is equipped with a range of features designed to optimize maintenance activities. One of the standout features is its ability to centralize all spare parts data, making it easy to access important information such as part specifications, locations, and inventory levels. The system's real-time data updates provide maintenance teams with up-to-date information on stock availability, ensuring that the necessary parts are always on hand when required.

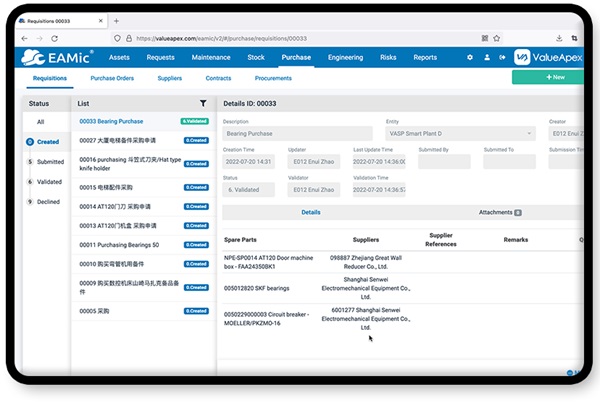

Additionally, the system supports advanced functionalities such as automated reordering, which streamlines the procurement process. When stock falls below a set threshold, the system automatically triggers reorder requests, saving time and ensuring that spare parts are always available. The integration of EAMic® with other enterprise systems, such as ERP and CMMS, ensures seamless data flow across the organization, further enhancing operational efficiency and coordination between departments.

The implementation of a spare parts management system like EAMic® offers several tangible benefits to businesses. By automating key processes, such as inventory tracking and procurement, the system reduces the chances of human error and streamlines workflows. The integration with other enterprise systems ensures that data is consistently up to date and accessible across the organization, improving collaboration and decision-making.

Furthermore, EAMic® provides maintenance teams with valuable insights into the usage and performance of spare parts. By analyzing data trends, companies can better forecast future demand, optimize inventory levels, and reduce the costs associated with excess stock or last-minute procurement. The system's predictive capabilities also help businesses transition from reactive to proactive maintenance, further improving equipment uptime and reducing the risk of unexpected failures.

In conclusion, a well-implemented spare parts management system is vital for maintaining the efficiency and reliability of industrial operations. With ValueApex's EAMic®, companies can transform their approach to spare parts management by automating inventory tracking, streamlining procurement, and providing real-time data insights. The system's ability to integrate seamlessly with other enterprise systems ensures that businesses can enhance their overall maintenance strategies, reduce downtime, and lower operational costs. By adopting a modern spare parts management system like EAMic®, organizations can stay ahead of the competition and ensure that their equipment is always in top condition.