Preventive Maintenance (PM) is the cornerstone for manufacturing enterprises to ensure equipment reliability and stable production. With technological advancements, PM has evolved from initial paper-based work orders to highly intelligent management systems. Factories employ a variety of PM management systems, all centered on the core philosophy of "preventing problems before they occur."

This is the most common and fundamental PM management system, serving as the starting point for digitalization for most companies.

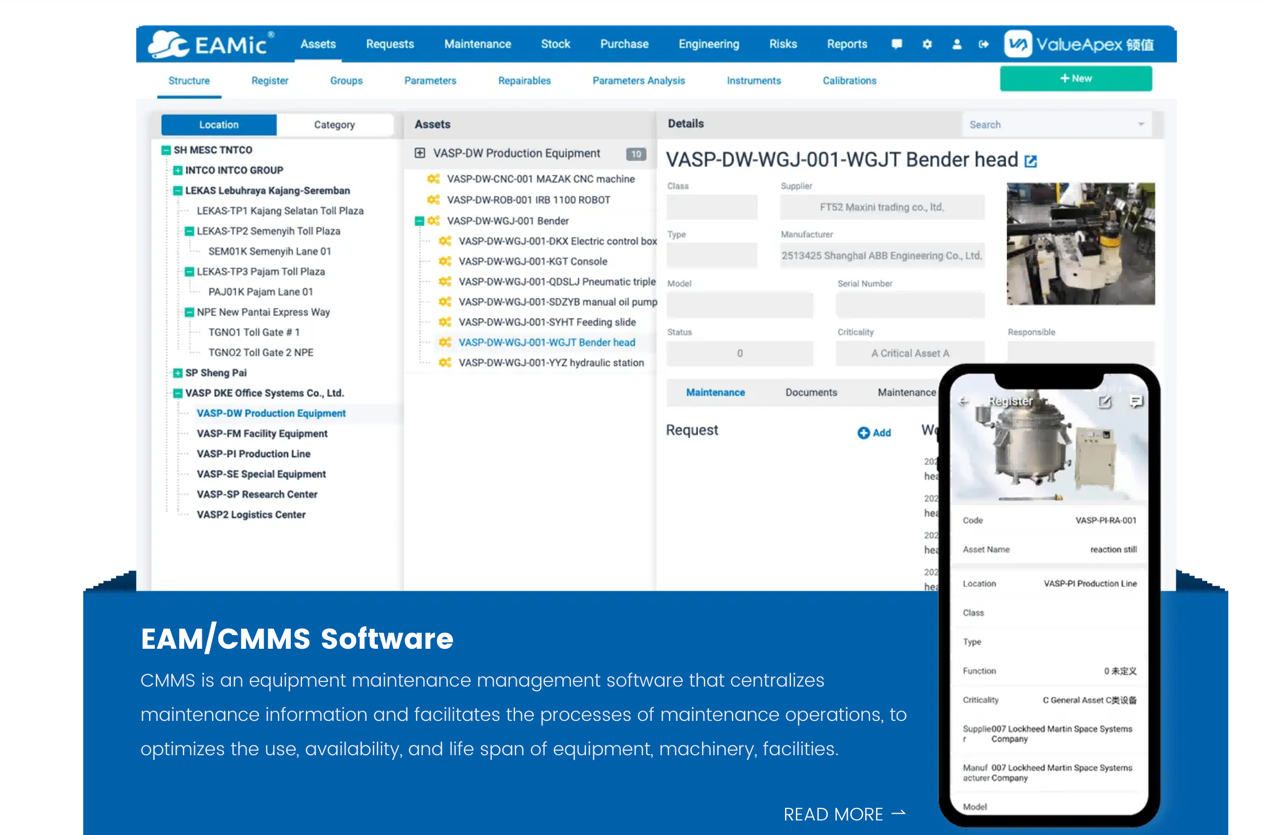

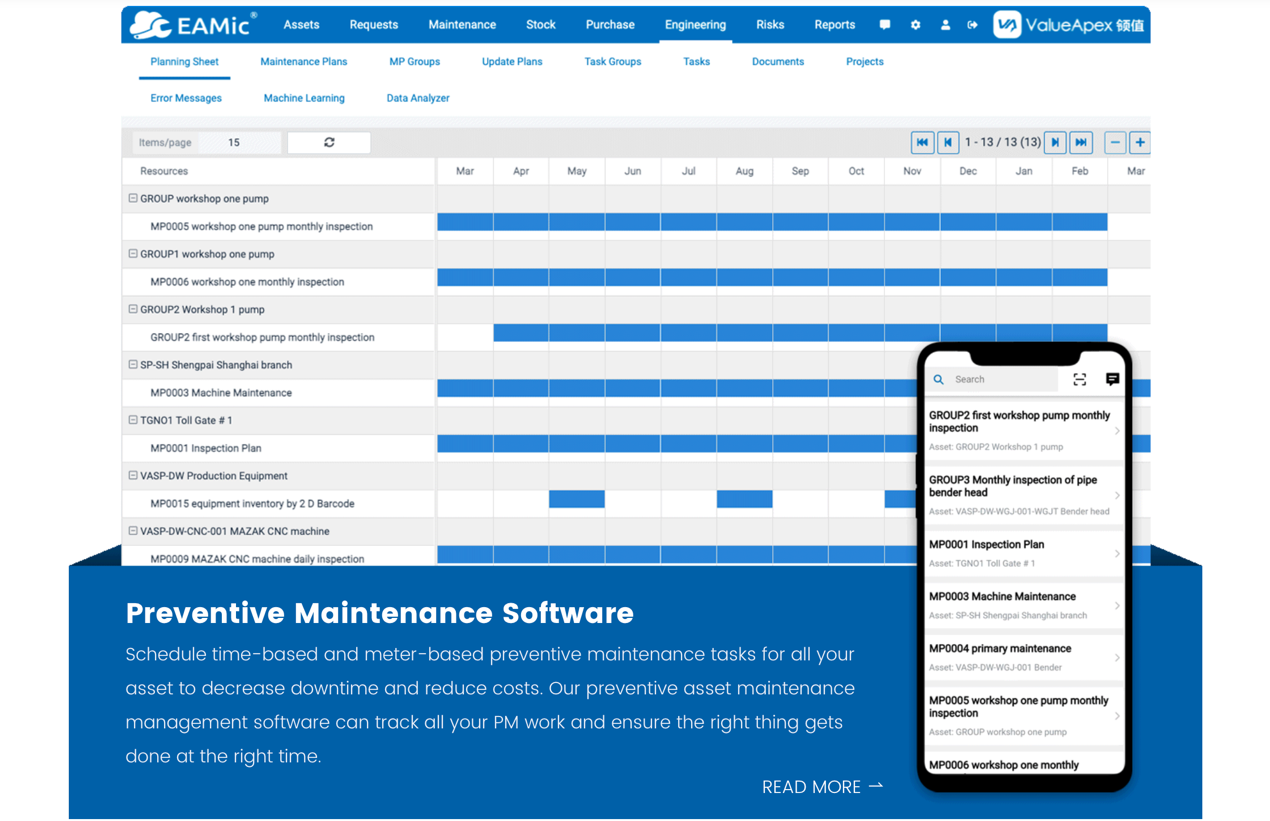

Core Functions: CMMS primarily focuses on the "management" aspect of maintenance work. Its core is establishing a database containing all equipment asset information and automatically generating preventive maintenance work orders based on time or equipment run-time counters.

Workflow: The system automatically creates PM work orders based on preset cycles or runtime thresholds, assigns personnel and required parts, and pushes tasks via email or mobile devices. Upon completion, engineers record labor hours, materials used, and issues found in the system.

Applicable Scenarios: Suitable for equipment whose failure modes have a clear and stable relationship with time or usage. It solves the inefficiency and error-proneness of paper-based management, automating scheduling and centralizing information.

Common Systems: Many traditional CMMS software fall into this category, such as Fiix, eMaint, and ValueApex EAMic.

This is an upgraded version of CMMS, using integrated IoT sensors and data collectors to make PM scheduling more precise.

Core Functions: Builds upon CMMS management capabilities by adding monitoring of real-time equipment condition data. The system can trigger inspection or maintenance tasks partly based on the actual condition of the equipment, not just fixed time intervals.

Workflow: Sensors continuously collect equipment data and upload it to the system. When a data parameter approaches but hasn't exceeded an alarm threshold, the system can automatically generate an inspection work order, alerting engineers to monitor the equipment and perform necessary adjustments or maintenance to prevent deterioration.

Applicable Scenarios: Suitable for critical equipment, aiming to convert some periodic maintenance into more targeted "condition-based maintenance," reducing unnecessary activities and saving resources.

Common Systems: Many modern cloud-native EAM and CMMS systems offer API interfaces for easy IoT platform integration, such as UpKeep, Limble CMMS, and modern versions of large EAM systems like SAP PM, IBM Maximo, and ValueApex EAMic.

This is a more advanced form of PM, falling under the realm of smart operations and strictly speaking, goes beyond the traditional definition of PM.

Core Functions: Utilizes big data, artificial intelligence, and machine learning algorithms to perform deep analysis on collected real-time equipment data, predicting the future probability of equipment failure and its remaining useful life (RUL).

Workflow: The system continuously learns the normal operating patterns of the equipment. Upon detecting anomalous patterns or predicting a failure trend, it issues an early warning sufficiently before the fault occurs and generates a very specific repair work order.

Applicable Scenarios: Suitable for high-value, complex equipment where failure causes significant downtime loss and has a discernible degradation process. Offers a very high return on investment but also has relatively high technical and financial barriers to entry.

Common Systems: Professional PdM software platforms like Augury, Senseye, Uptake, and predictive analytics solutions offered by some major industrial software vendors.

Many large Enterprise Resource Planning (ERP) or Manufacturing Execution Systems (MES) have built-in PM functional modules.

Core Functions: As a sub-module of ERP/MES, its PM functionality might be similar to standard CMMS, but its greatest advantage lies in data integration. Equipment maintenance data can flow seamlessly with procurement, finance, and production data.

Workflow: When a PM work order is generated, it can directly link to the procurement module to request spare parts; maintenance costs can be directly posted to the finance module for calculating Total Cost of Ownership; overhaul plans can be coordinated with the MES module for production scheduling.

Applicable Scenarios: Suitable for large group companies that have already deployed a core ERP or MES system and wish to achieve integrated business process integration.

Common Systems: SAP EAM, Oracle EAM, Infor EAM.

Choosing which PM management system depends on the company's equipment complexity, budget, digital maturity, and strategic goals. For most companies, starting with a "modern, cloud-based CMMS" is a solid path. For companies with critical equipment, considering an "IoT-integrated CMMS" is advisable. For industry leaders, investing in "Predictive Maintenance (PdM)" will be key to building future competitive advantage. Understanding the distinctions and connections between these systems is the first step towards successfully implementing a PM strategy and achieving intelligent transformation.